|

|

|

|

The

Britannia Universal Rotary Soap Stamping Press is a

design combining modern technology with traditional

practice. The mechanism is designed and constructed like

a high precision Swiss watch with all the moving parts

held between two massive steel plates. All the immense

forces channelled into deforming the soap by pressure,

are controlled and directed with the highest degree of

precision and reliability. |

|

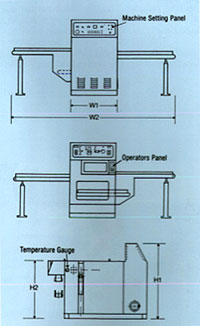

TYPE:

QRX ROTARY 590 |

|

|

|

FUNCTION: To stamp the pre-cut soap billets

into the finished tablet shapes |

|

|

|

FEATURES: |

- Double stamping

action

- Multi-cavity soap

dies to fit 590 mm mandrel

- Stamping cycle time

in the range of 15 to 75 strokes per minute

- External handwheel

adjustments for rapid die (product) change

- Operator given

maximum access to dies

- Machine designed to

minimise scrap recycle percentage

- Brake stops the

stamper with dies in open position to ease cleaning

- 5.5 kW main drive

motor

- Electronic

air/vacuum programmer is standard on control panel

|

|

OPTIONS: |

- Temperature control

of die chilling to mandrel and ram

- Internally fitted

vacuum pump

|

|

GENERAL DESCRIPTION

A horizontal type stamping machine with a rotating

mandrel on which are mounted two die blocks, and an

oscillating ram on which on die block is mounted. The

machine includes the die holders, single infeed and

outfeed conveyors, and cam designed stamping movement.

The machine included the facility for both air powered,

and mechanical soap ejection. The mechanisms are all

enclosed in a fabricated steel frame, complete with

safety guards and an active lubrication system.

|

|

|

The

soap billet is fed into the machine by mans of an infeed

conveyor, it is then lifted into place by a soap lifting

mechanism. It is stamped to shape by a double action

stamping movement of the ram, then the soap is rotated

in the mandrel to the unloading postion. The soap tablet

is pulled through a de-flashing stripper plate by a

rubber vacuum operated sucker, and placed on an offtake

conveyor ready for feeding into a wrapping machine.

Excess flash drops by gravity, and is usually recycled

via scrap return conveyors to the hopper of a duplex

vacuum plodder. The soap dies incorporate large chilling

galleries for the circulation of a low temperature

refrigerant which prevents soap sticking in the

cavities. |