|

|

The

Britannia Company offers a range of machinery for

cutting the extruded soap bar exiting from the final

plodder. The bar can be either cut into billets for

presentation to the Stamping machine or into blocks of

finished laundry soap. All our machines are automatic

and are offered as either fixed billet sized knives or

variable billet adjustable knives.

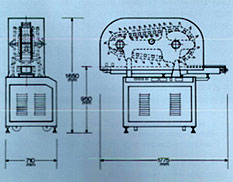

The Britannia Varimax Soap Cutter cuts an extruded soap

bar into billets with a new order of accuracy. The metal

cutting chain links are cut by laser to a high degree of

precision, to give soap bars which are accurate in

length and exhibit a clean, square finish.

|

|

The

Britannia Varimax Soap Cutter is a solidly constructed

machine using all steel fabricated parts for the

supports and framework. This gives an extremely stable

machine completely free from twisting or distortion, and

guarantees the maximum accuracy of cut.

The cutter supports are solid steel to completely

eliminate flexing, and they are cut to accurate

tolerances by high technology lasers.

The articulating drive links are specially fabricated

aluminium metal to combine high strength with light

weight and correspondingly low inertia. This permits the

cutting chain to respond immediately to change of speed

in the extruding soap bar without any tendency to

distort or drag the soap.

The cutting machine, for incorporation into high speed,

fully automatic manufacturing lines, uses a brand new

and unique drive system that is the best available.

Variable speed is provided by an adjustable voltage

direct current motor which uses positive feedback to

maintain precise velocity settings.

Variable torque is provided by a manually adjustable

clutch type coupling where the variation in soap

hardness can be compensated for by an adjustable

control.

It is possible to “slave” together the plodder, cutter

and stamper to all run at exactly the same speed for

fully automatic production.

We offer an alternative design of drive system where it

is not considered desirable to tally automate the

manufacturing line. The Varimax (air) is driven by a

pneumatic motor working off compressed air. By varying

the air pressure it is possible to vary the speed and

torque of the cutting chain.

The cutting chain head on both systems is variable for

angle so that extra thick billets can be cut with true

accuracy.

The fixed type cutting machine is the most economically

priced unit and the cutting chain is mounted on a light

weight support frame. If it is required to change the

size of the cut billet then it is necessary to stop the

machine and unscrew the cutting assembly. This is then

manually lifted off the alternative size of cutting

chain is bolted into place. This operation requires no

skill and occupies about 10 minutes. The extra chain

sizes are specially prepared to the clients specified

dimensions.

|

|

|

The

standard cutting range is 65mm to 110mm but it is

permissible to remove blades to vary the cutting length.

For instance, if every alternate blade is removed from

the standard chain then the 65mm to 110mm becomes 130mm

to 220mm if only every third blade is left in place,

then the standard chain will adjust between 195mm and

330mm. |